Flux Cored MIG Welding Wire Production Line Features

· Automated Control System: The Flux cored MIG welding wire production line has an automated control system that allows for easy operation, reducing the need for manual intervention.

· High Output Speed: The flux cored MIG welding wire production line features high output speed, allowing large-scale production of welding wires.

· Energy-saving System: The equipment has an energy-saving system that reduces power consumption without compromising the quality of welding wires.

· High-Quality Welding Wire Production: The flux cored MIG welding wire production line produces high-quality welding wire with significant strength, ductility, and corrosion resistance.

· Consistent Production Output: You can count on producing consistent output quality with this production line.

Flux Cored MIG Welding Wire Production Line Benefits

· Improved Efficiency: The automated control system of the flux cored MIG welding wire production line streamlines the welding wire making process, saving time and reducing costly errors.

· Reduced Production Cost: The equipment has an energy-saving system that minimizes electricity consumption, reducing production costs and increasing profitability.

· High Production Capacity: With the high production capacity of the production line, you can meet the growing demand for welding wires and remain competitive in the market.

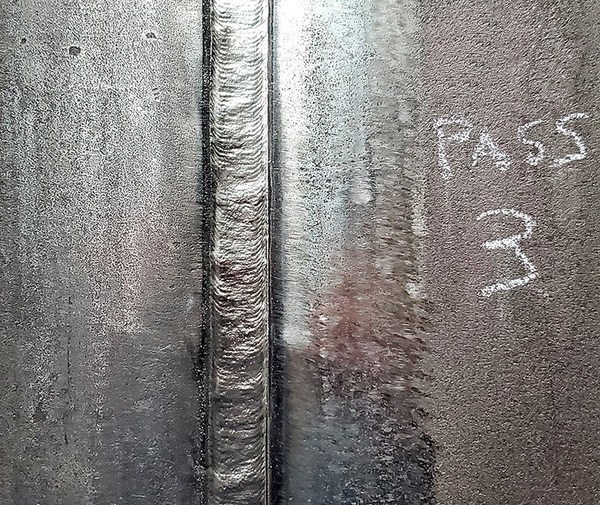

· Unmatched Quality Welding Wires: The flux cored MIG welding wire production line provides welding wires of unmatched quality and performance, ensuring customer satisfaction.

Manufacturing Process of Flux Cored MIG Welding Wire Production Line

The Flux cored MIG welding wire production line is designed to cater for the continuous production of welding wires. The following is an overview of the manufacturing process:

1. Feed Raw Materials: The raw materials, including carbon steel wire, flux, and alloy powder, are fed into the production line.

2. Wire Drawing: The raw wire is drawn through a wire drawing machine to form a narrow wire.

3. Flux Filling: The narrow wire is passed through a flux filling machine that fills the flux into the wire.

4. Powder Filling: The wire is then passed through a powder filling machine that fills the alloy powder.

5. C1 Cylinder Welding: The wire is welded to the C1 cylinder through the cylinder welding machine.

6. Wire Forming: The wire's final shape is obtained through the wire forming machine.

7. Packaging: The finished welding wires are packaged in spools, ready for use.

Conclusion

The Flux cored MIG welding wire production line manufactured in China is a highly efficient, energy-saving, and reliable production system for the continuous production of high-quality welding wires. It comes with innovative features and unbeatable benefits that ensure a profitable ROI for all welding professionals. By choosing to use the flux cored MIG welding wire production line, you will enjoy faster, more efficient, and consistent manufacturing of welding wires that meet your customer's needs. For more information on MIG wire production line solutions, contact your local Chinese manufacturers today.